Description

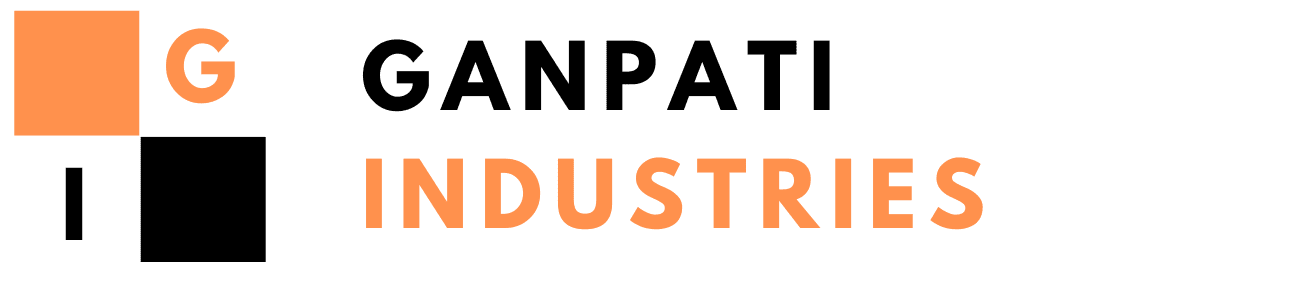

316 stainless steel has excellent corrosion resistance in many environments. This austenitic stainless steel contains 16–18% chromium, 10–14% nickel, 2–3% molybdenum, 0.08% carbon, and trace amounts of other elements. The addition of molybdenum differentiates it from the most commonly specified stainless steel, 304, and gives 316 much better corrosion resistance than T304. It has a face-centred cubic (FCC) arrangement of atoms and a crystalline structure. Its high strength and toughness are due in part to this configuration.

Uses of 316 Stainless Steel Sheet

Numerous industries and applications make extensive use of 316 steel. Listed below are some examples:

- It is often employed in food handling, cooking, and storage equipment due to its durability, ease of cleaning, resistance to bacterial growth, and non-reactivity with food.

- It is suitable for handling corrosive chemicals and acids, making it popular in chemical plants and refineries.

- It is highly corrosion-resistant in marine environments, making it ideal for boat fittings, marine hardware, and offshore structures.

- It is biocompatible, making it suitable for surgical instruments and implants.

316 Stainless Steel Sheet:

- Exceptional corrosion resistance: Ideal for harsh environments like chemical plants, marine settings, and food processing. Expand_more

- Durable and easy to clean: This makes it perfect for food handling equipment, surgical instruments, and boat fittings.

- Strong and tough: Thanks to its face-centred cubic crystal structure. Expand_more

- Available in various sizes and thicknesses: To suit your specific project requirements. Expand_more

Visit Our Other Branch: Ganpati Industries, Arc Stainless

Reviews

There are no reviews yet.